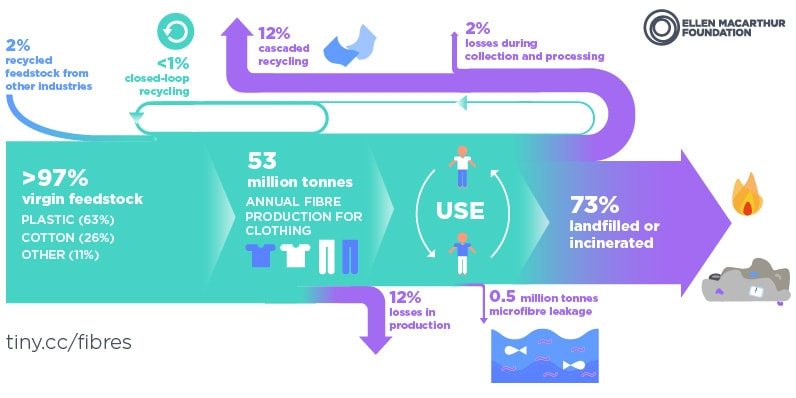

𝗟𝗘𝗦𝗦 𝗧𝗛𝗔𝗡 𝟭% 𝗢𝗙 𝗧𝗛𝗘 𝗠𝗔𝗧𝗘𝗥𝗜𝗔𝗟 𝗜𝗡 𝗖𝗟𝗢𝗧𝗛𝗜𝗡𝗚 𝗜𝗦 𝗥𝗘𝗖𝗬𝗖𝗟𝗘𝗗 𝗜𝗡𝗧𝗢 𝗡𝗘𝗪 𝗚𝗔𝗥𝗠𝗘𝗡𝗧𝗦 • So, how do we change this?

Globally, most of material that goes into clothing ends up either in landfill or an incinerator (about 73% of all material produced.)

885 words, 4 mins read

Above feature photo: 2015 Global Material Flows. Source: Circular Fibres Initiative

Textile waste consumes nearly 5% of all landfill space, and 20% of all freshwater pollution is a result of textile treatment and dyeing. Growing cotton requires harmful pesticides and fertilisers, and textile-manufacturing plants release hazardous waste into land, water, and atmosphere. Extracting oil, a non-renewable resource to make plastics for clothing, is also problematic.

We will consume more textiles

The demand for textiles will rise significantly, as the global population reaches 8.1 billion by 2025. By the mid-century, this figure will be 9.5 billion, and close to 11 billion by 2100. #Asia will shfit from being the world’s largest textile manufacturer and supplier to becoming world’s biggest consumer of textiles.

Hence, the need for better recycling options for fibres.

Turning waste back into fibres with #technology

Most garments that are #recycled are down-recycled. The biggest issue holding back garment-to-garment recycling is fibre quality: fibres are damaged during both wearing and washing. You cannot take a well-used shirt, mechanically tear it apart and then make the fibres into a new shirt, because they have lost so much fibre quality that the shirt will not be of high enough quality to fit into the market.One option is to mix mechanically recycled fibres in with virgin fibres. This has been a popular option for #polyester and #nylon, the material of choice that has been incorporated into many brands we are familiar with today: H&M’s Conscious Collection catalogue is full product offerings containing recycled polyester and virgin polyester blends, Patagonia has been making recycled polyester from plastic soda bottles since 1993, turning trash into fleece, and Adidas has been using abandoned fishing nets from the sea to make adidas x Parley training wear that is made of at least 75% upcycled plastic trash.

The Lifecycle of a typical garment. Source: Green Strategy.

Another possibility is to chemically break fibres down into their chemical building blocks and then rebuild them into new fibres with indistinguishable performance characteristics than virgin fibres. Only with a chemical approach can we get the raw materials back and close the loop on textile recycling.

One example is NAIA™ Renew yarn, developed by Eastman, a product resulting out of a chemical recycling process. The company describes it as “a cellulosic yarn sourced from 100 percent circular content, produced from 60 percent certified wood fibres and 40 percent recycle waste plastics.”

Another is re:newcell, a product that turns used cotton and viscose into new biodegradable pulp, new fibers, and new yarn. Their #recycling technology transforms high cellulosic waste into pure, natural dissolving pulp, Circulose pulp.

Deakin University in Australia has also developed a similar solution for recycling textiles that involves dissolving cotton and regenerating it into brand-new #cellulose – a complex, strong carbohydrate with many industrial uses.

In all of these examples above, the new fibre is 100% biodegradable, so as not to add to the textile waste problem.

H&M Foundation, in partnership with HKRITA, The Hong Kong Research Institute of Textiles and Apparel, has also successfully discovered a hydrothermal method that can break down blended textiles to make long, good quality polyester fibres. The ‘Green Machine’ can take 100 kilograms of fabric per day and planned to reach 1,000 kilos per day within one year since its launch in September 2018.

Re:newcell turns used cotton into Circulose at their plant in Kristinehamn, Sweden.

Full circularity Is the way to sustainability

Of course, recycling fibres by harvesting textiles at its end-of-life is only but one way to tackle fashion’s #sustainability woes. Given there are so many clothes produced in any given year, it is imperative that growth is slowed right back down.

#Covid19 has presented the perfect opportunity for both consumers and producers alike to consume and produce differently. Gen Zeds are already buying less new stuff, and preferring to buy pre-loved and #secondhand during isolation, as this recent report had found. So many of us have taken up at-home skills such as #mending and upcycling our old clothes.

As the fashion industry grinds to a near-halt, brands are cancelling orders, laying off employees and quickly repositioning marketing messages to account for store closures and customers being stuck at home. In a global crisis, sustainability commitments often fall to the wayside, and most brands are predictably keeping quiet about their ambitions now.

To become circular, the fashion industry needs to make fundamental changes in three key areas: product design, infrastructure and business models. It’s not just about reusing fabric again and again, but also considering external impacts, such as greenhouse gases and water contamination with toxic chemicals, that might be generated. This means we are designing out pollution. If we also design with reuse and recyclability in mind, for example, producing clothes from single-material fabrics, how quicker and easier can we get to realising circularity?

For a full understanding of The Principles of Circular Fashion, this article sums it up for you.

There is no proof or precedent, however, that an economic setback will result in sustainable investments, but if you had a choice to produce differently, wouldn’t now be the right time to set things up right?

Join us in our Slow Fashion movement with the hashtags #ConscientiousFashionista and #wardrobetruths on Instagram, and follow us at @fashinfidelity.

Tags: #circularfashion #circularity #ethicalfashion #sustainablefashion #ecofashion #greenfashion #responsiblefashion #recycledyarn #recycledfabric #recycledcotton #fabricrecycling #recycling #conscientiousfashionista #fastfashion #slowfashion #sustainability #wardrobetruths #fashioneducation #fashion #fashinfidelity #pandemic #covid

We can recycle more than 1 percent, and now is the perfect time to aim higher! With advancements in recycling technology and increased awareness of the environmental benefits, the potential for boosting recycling rates is greater than ever. By educating communities, improving access to recycling facilities, and encouraging innovation in product design to make materials more recyclable, we can significantly reduce waste and conserve resources. Small individual actions, when multiplied, can lead to transformative change, making this an achievable and urgent goal for the betterment of our planet.